Swaine & Adeney's Luggage Legacy

Swaine's heritage lies in whip-making, but with the advent of automobiles, the industry underwent a transformation. Swaine adapted by shifting its focus to crafting luggage for automobiles, a strategic move that laid the foundation for the Swaine we know today.

Swaine & Adeney (1848-1910)

In the late 1890s, automobiles emerged as "horseless carriages" on the roads, marking a transformative era. Embracing innovation, Swaine & Adeney redirected their expertise in leather working towards crafting luggage sets tailored for these new motor vehicles. Unlike the widespread accessibility of railways, car ownership remained exclusive to the affluent until WWII.

Swaine & Adeney Ltd (1910-1943)

Edward Swaine's booklet, "Good Hands" (1750-1927), produced by Baynard Press, stands as a fine piece of work. In it, Edward emphasised his openness to technological advancements and progress, dispelling any notion of being anti-machine.

Edward dedicated his booklet to those committed to preserving the esteemed tradition of English craftsmanship in an era overshadowed by machine production. His enduring idealism continues to resonate through its pages, nearly a century later.

The booklet also depicts the changing landscape of the 1920s, illustrating a strategic shift to thrive in an era of mechanisation. Furthermore, it underscores their adaptive strategy through the expansion into motoring luggage, including handbags and document cases.

They expanded their range to include handbags and document cases for monitoring purposes. In the 1920s, they further diversified by introducing a wide selection of handmade leather gloves, a move recognised in 1931 with a royal warrant as glove makers to George V. Edward also advocated for the company's commitment to customising goods to meet individual customer needs, including crafting luggage to fit precisely in the trunk of specific car models.

Swaine Adeney Brigg & Sons (1943-1990)

During the 1960s, Swaine Adeney Brigg & Sons prioritised excellent design, refining their luggage collections to embody the sleek, modern aesthetic and evolving preferences of the era while maintaining uncompromised quality.

This shift was notably evident in the women's department, where vibrant umbrellas emerged amidst the classic black silks, and sleek, angular handbags and vivid red vanity cases contrasted with the traditional briefcases.

Swaine Adeney Brigg 1990-2010

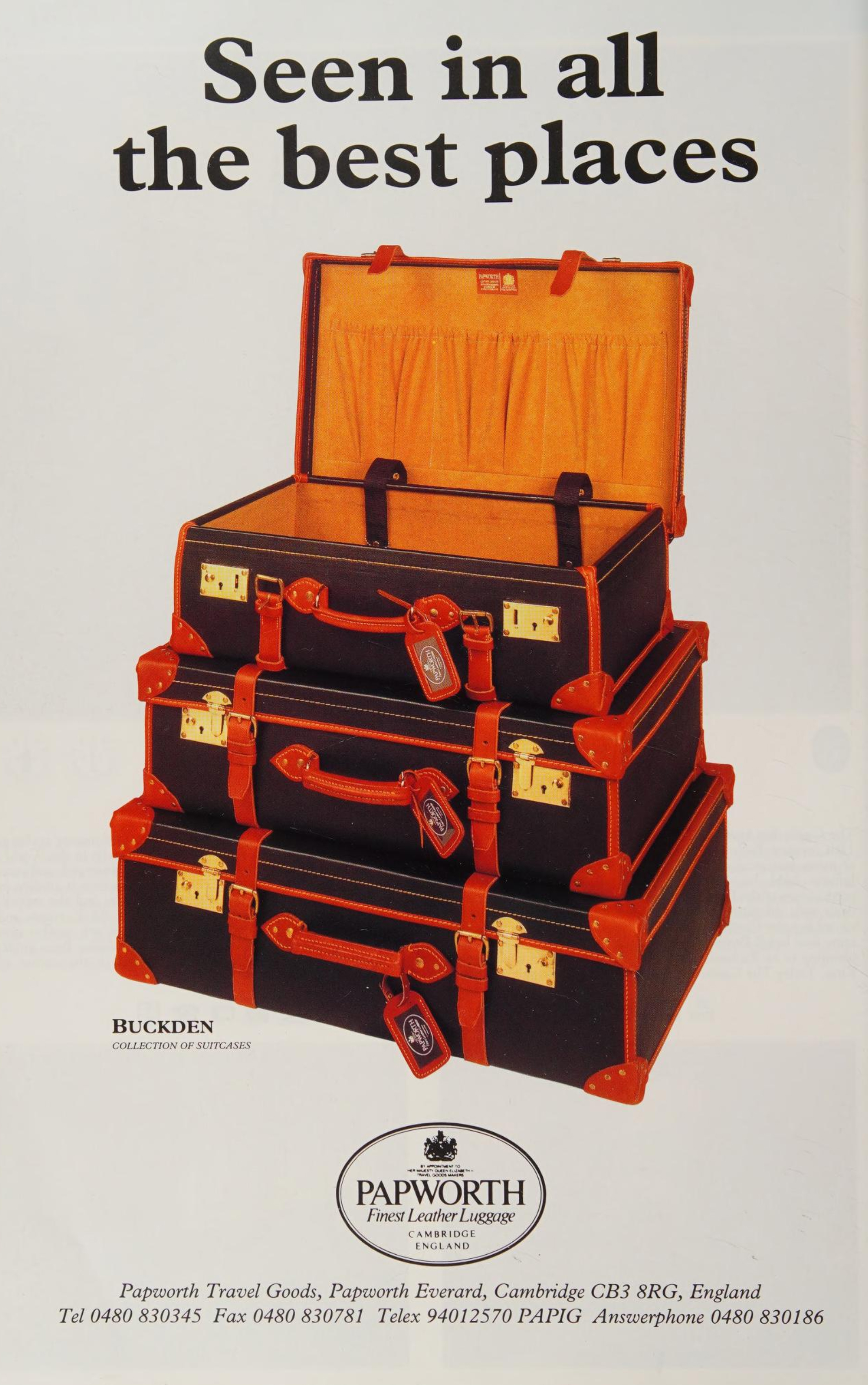

At that juncture, the company chose to realign its efforts towards its primary focus: the luggage range. By 1996, Swaine Adeney Brigg was producing 2,500 briefcases annually, with this capacity further bolstered in 1997 through the acquisition of Papworth Industries luggage making department.

Numerous facets of the business seamlessly aligned with the ethos of Swaine Adeney Brigg, including a fervent dedication to quality craftsmanship, a rich history of royal patronage, and the deeply rooted involvement of one family in the company's operations.

As the new century unfolded, Papworth and its products remained synonymous with the name Swaine Adeney Brigg.

Papworth Industries

James Alexander Box, born in London in 1890, was the son of a saddler in Greenwich. Initially assigned as a Saddler to the Royal Field Artillery, he was deemed unfit for service in 1918 due to a tuberculosis diagnosis. Sent to Papworth, he leveraged his leather working expertise to establish the trunk-making department. Remarkably swiftly, Papworth Industries' trunks and cases found their way into esteemed London outlets like Selfridges department store.

Transitioning back to civilian production after the war posed a significant challenge for the trunk making department. Production methods, supplies, and market conditions had undergone drastic transformations.

Air travel presented hurdles as well, necessitating lightweight yet durable luggage. This shift prompted changes in both shape and construction materials. Traditional square corners and full-grain leather gave way to rounded corners, plywood frames, and moulded bases, replacing individually crafted ones.

Plastics played a crucial role in the creation of soft-bodied luggage, including foldable suit bags or a "hanging wardrobe". However, these innovations posed challenges for the trunk making department, with many senior workers resisting the shift to new styles, materials, and increased mechanisation.

However, the department remained connected to its origins in hand-made leather goods. Despite a decline in interest from the mass market for hand-stitched cases, there remained a niche of discerning clients willing to invest in full-grained leather suitcases and attachés crafted in the traditional manner. In response to this demand, Papworth Industries continued to train new artisans in the traditional craft whenever opportunities arose.